Importance of Electrical & Instrumentation Services for Industrial Operations in Sharjah

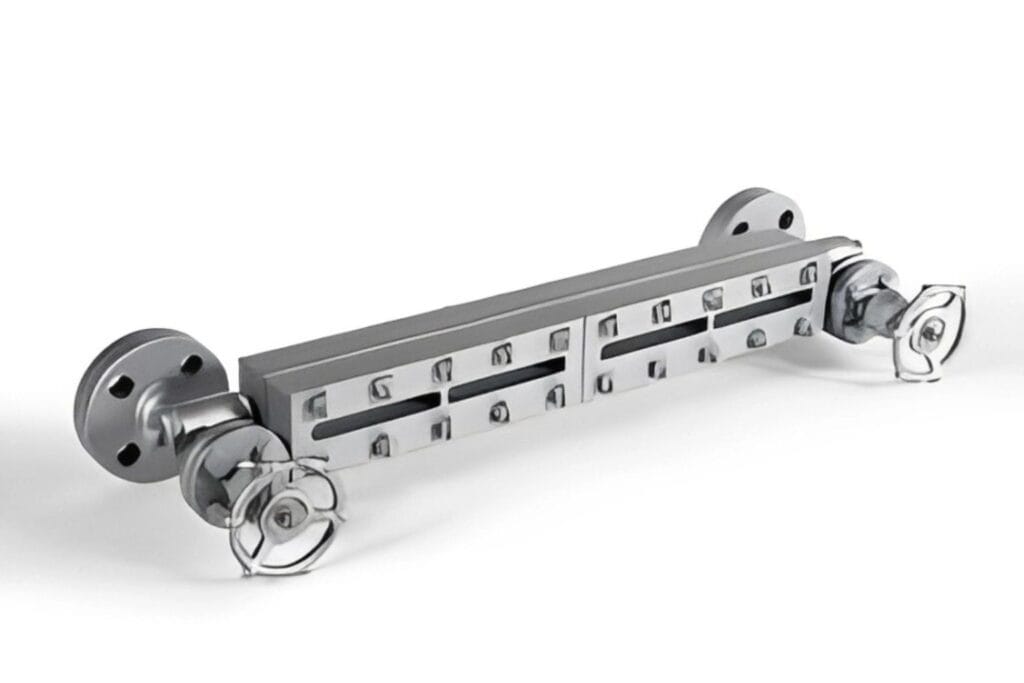

Electrical & Instrumentation Services need for dependable and effective operations is critical in Sharjah, a booming industrial center. For industrial facilities to operate efficiently, electrical and instrumentation (E&I) services are essential. In addition to machine maintenance, these services promote safety, maximize efficiency, and ensure long term operational dependability. Ensuring Safety In any industrial setting, safety comes first, and E&I services are essential to making this happen. Electrical defects, short circuits, and possible fire threats are reduced by well designed and installed electrical systems. Accurate readings and dependable operation are guaranteed by instrumentation services like sensor and monitoring device calibration. This accuracy aids in avoiding risky circumstances that could endanger worker safety and environmental health, such as equipment failures or hazardous chemical spills. Enhancing Efficiency Reducing operating expenses and increasing production both depend on efficiency. E&I services provide a substantial contribution by automating procedures, enhancing system integration, and optimizing energy use. Well maintained equipment guarantees efficient operations and efficient use of resources in sectors like manufacturing and oil & gas where accuracy is crucial. These services assist Sharjah facilities in maintaining their competitiveness in international markets by cutting waste and downtime. Improving Reliability Meeting production goals and preserving customer satisfaction depend on dependable operations. For electrical systems to meet the needs of industrial processes, they must be reliable and strong. Unexpected malfunctions and expensive delays are avoided with E&I services’ regular maintenance and improvements. Likewise, accurate instrumentation lowers the possibility of operational disturbances by guaranteeing consistent process monitoring and control. Compliance with Regulations Strict regulatory frameworks govern Sharjah’s sectors to guarantee that operational and environmental criteria are fulfilled. E&I services ensure system integrity, satisfy international safety and quality requirements, and provide accurate paperwork to assist facilities in adhering to these rules. In addition to avoiding legal problems, compliance improves the facility’s reputation. Supporting Technological Advancements Advanced technologies like IoT, AI, and machine learning are being adopted by Sharjah’s industries more and more. In order to integrate new technologies into current systems and enable data driven decision making, predictive maintenance, and real time monitoring, E&I services are essential. This progressive strategy guarantees that facilities continue to lead the way in innovation. Globe United Delivering Safety and Excellence Industrial facilities are guaranteed to receive excellent E&I solutions that are customized to meet their specific demands when they collaborate with seasoned providers like Globe United. Globe United is dedicated to providing these services while upholding the strictest safety regulations, guaranteeing dependable and effective operations for each industrial project.

Importance of Electrical & Instrumentation Services for Industrial Operations in Sharjah Read More »