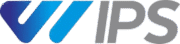

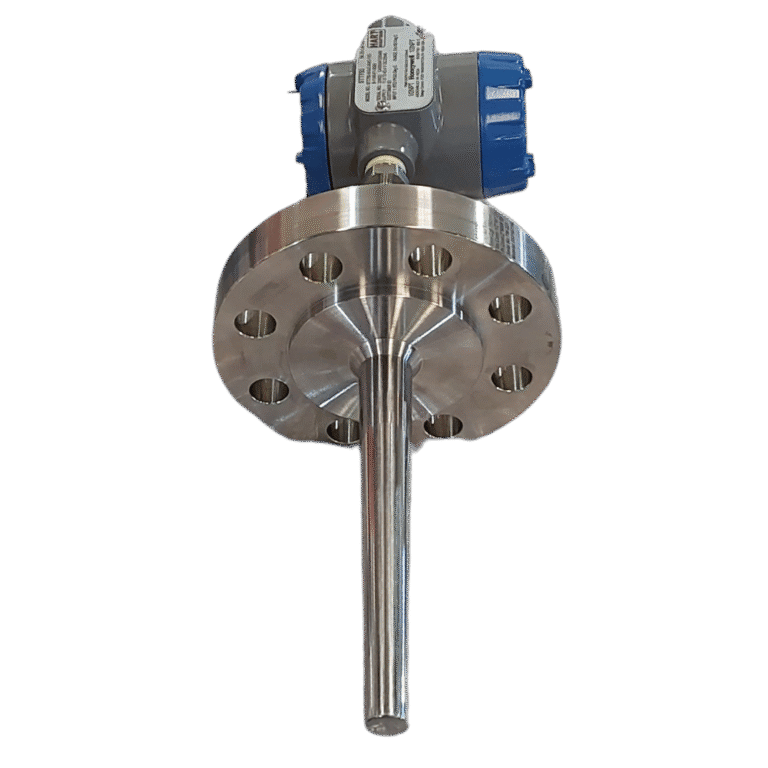

Flushing Rings

Efficient Cleaning and Maintenance

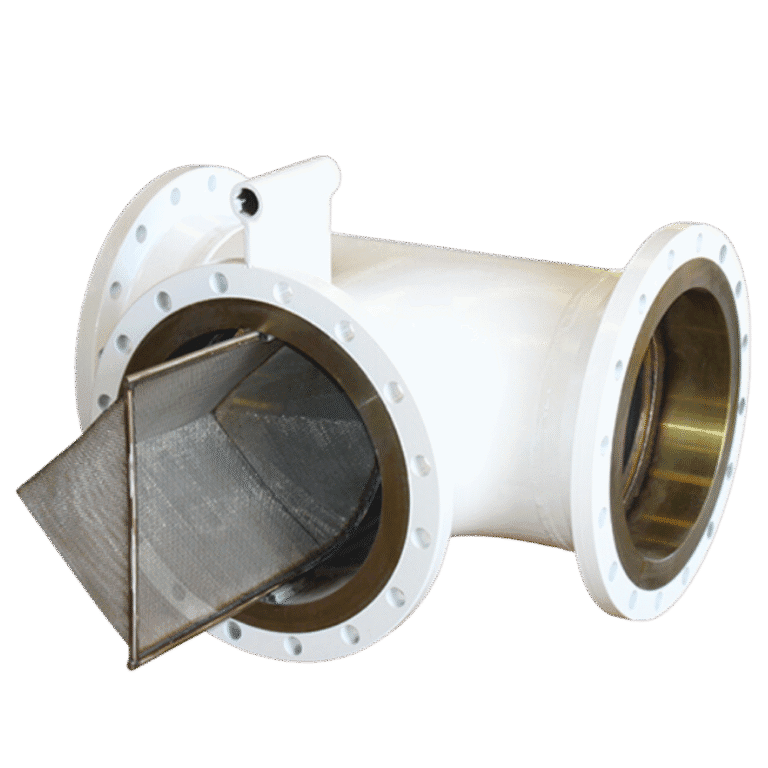

Designed to provide a pathway for flushing fluids, allowing for the effective cleaning of diaphragm seals.Prevents the buildup of residues and contaminants, ensuring accurate pressure measurements.Robust Construction

Manufactured from high-quality materials such as stainless steel, Hastelloy, and other corrosion- resistant alloys.Suitable for high-pressure and high-temperature applications, providing long-term durability and reliability.Versatile Design

Available in various configurations and sizes to suit different diaphragm seal and process requirements.Can be used with a wide range of fluids, including corrosive and hazardous substances.Easy Installation and Maintenance

Designed for straightforward installation between the diaphragm seal and the process connection.Simple to remove and reinstall, facilitating easy maintenance and inspection.Customizable Options

Available in different sizes, materials, and pressure ratings to suit specific application needs.Custom-designed flushing rings can be provided to meet unique process requirements.Technical Specifications

| Measuring Range | Material Options: Stainless steel, Hastelloy, Inconel, and other corrosion-resistant alloys. |

| Operating Temperature | Operating Temperature: Suitable for temperatures up to 400°C (752°F) or higher with special designs. |

| Operating Pressure | Operating Pressure: Can withstand pressures up to 150 bar (2175 psi) or higher with reinforced construction. |

| Material Options | Sizes: Available in standard sizes ranging from 1/2 inch to 4 inches, customizable to meet specific application requirements. |

| Float Size and Material | Connection Types: Flanged, threaded, or welded connections for easy integration into existing systems. |

| Indicator Board | Optional Features: Custom configurations and additional ports for enhanced functionality. |

Applications

Oil and Gas

Oil and Gas Cleaning and maintenance of diaphragm seals in pipelines, refineries, and offshore platforms.

Chemical Processing

Water Treatment Maintaining diaphragm seals in water and wastewater treatment plants to ensure reliable pressure readings.

Water Treatment

Power Generation Flushing of diaphragm seals in boiler feedwater, steam, and cooling water systems in power plants.

Food and Beverage

Food and Beverage Cleaning diaphragm seals in hygienic applications to ensure accurate pressure measurements in food and beverage production processes.

Downloads

Benefits

Flushing Rings are essential for industries requiring efficient and reliable cleaning and maintenance solutions for diaphragm seals. With their robust construction, versatile design, and high- performance capabilities, our flushing rings ensure optimal pressure measurement accuracy and process reliability. By choosing our flushing rings, you benefit from enhanced process control, improved safety, and long-term operational efficiency.For more information or to request a quote, please contact us at sales@globeunitedae.com.

- Enhanced Process Reliability:

Ensures accurate and reliable pressure measurements by preventing contamination buildup.

- Improved Safety:

Facilitates safe and effective cleaning of diaphragm seals, protecting operators and equipment.

- Cost-Effective:

Durable construction and low maintenance requirements contribute to reduced long- term operational costs.

- Flexible Integration:

Wide range of sizes, materials, and customization options make it easy to integrate the flushing rings into various systems and applications.

- Compliance with Standards:

Conformance to industry standards ensures reliable and consistent performance across diverse applications.

We offer quality with the best materials and service

We offer quality, with the best materials and service

Our commitment to excellence is reflected in every product and service we deliver. Using only premium materials and advanced processes, we ensure unmatched quality, durability, and performance tailored to your needs.

Original Product

Inhouse Engineered, Innovative, Excellent product to redefine your expectations and embrace the extraordinary.

Warranty

We are confident about our quality products and covered our warranty to ensure client satisfaction.

Global Shipping

We offer our products Worldwide and we want you to experience our exceptional product at your doorstep. With Global customer base, We have earned trust globally.

100% Trust

Our commitment to 100% trust on our engineered product. Client trust is our most valued asset.