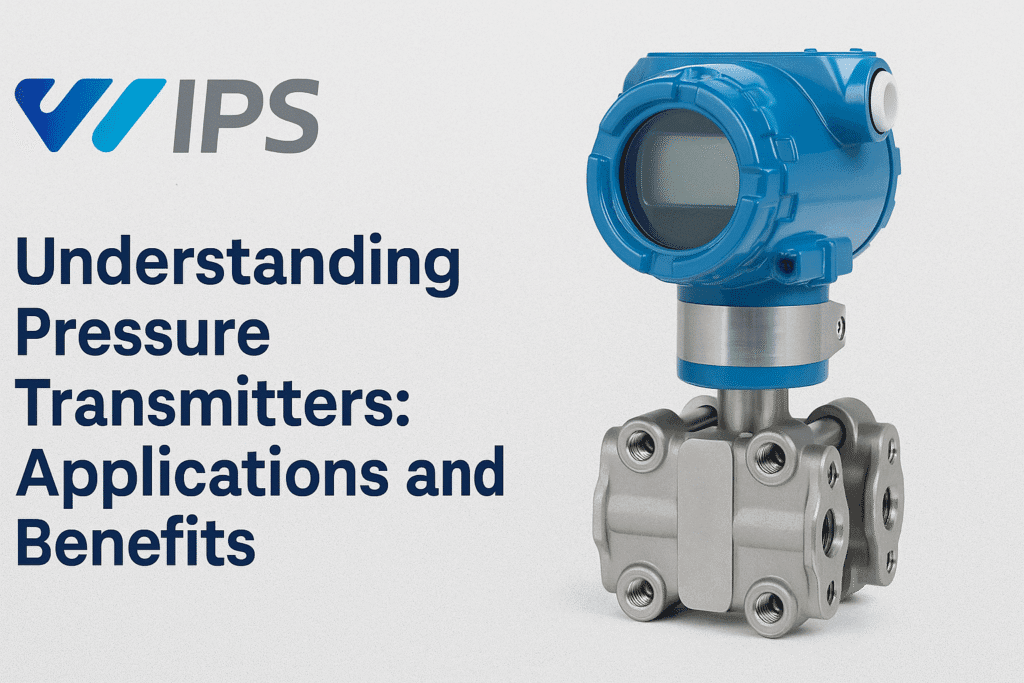

In today’s fast-moving industrial world, precision and reliability are not optional—they are critical. Whether it’s monitoring oil flow in a refinery or ensuring accurate water pressure in a treatment plant, one unsung hero often behind these operations is the pressure transmitter.

But what exactly is a pressure transmitter? How does it work, and why should industries care about it?

Let’s break it down.

What Is a Pressure Transmitter?

A pressure transmitter is a sensor device that measures the pressure of gases or liquids and converts that data into an electrical signal. This signal is then used by control systems to monitor and regulate processes in real-time.

Imagine it as the “ears” of your automation system—it listens to what’s happening in the pipeline or tank and tells your machinery exactly how to respond.

How Does It Work?

Here’s a simple explanation:

- Sensing Element – detects the pressure of the fluid or gas.

- Transducer – converts this pressure into an analog electrical signal.

- Transmitter – amplifies and sends the signal to a control unit or display.

In many advanced systems, this data can be monitored remotely or even integrated into cloud-based platforms for real-time decision-making.

Applications Across Industries

Pressure transmitters are used almost everywhere industrial automation is present. Here are some key sectors that rely on them:

1. Oil & Gas

- Monitoring pipeline pressure

- Preventing overpressure damage

- Ensuring safe and efficient extraction

2. Water & Wastewater

- Maintaining consistent flow in treatment plants

- Avoiding pump cavitation

- Monitoring pressure in filtration systems

3. Food & Beverage

- Ensuring hygiene in pressurized systems

- Monitoring temperature-compensated pressure

- Improving batch consistency

4. Pharmaceuticals

- Maintaining precise pressure levels for sterile production

- Supporting compliance with stringent quality standards

Why They Matter: Key Benefits

Enhanced Process Control

Accurate pressure readings allow operators to fine-tune processes, minimize downtime, and avoid costly mistakes.

Improved Safety

Uncontrolled pressure can lead to leaks, explosions, or system failure. Pressure transmitters help mitigate such risks.

Efficiency and Cost Savings

By detecting issues early and optimizing operations, businesses save on energy, materials, and maintenance.

Data-Driven Decisions

Real-time data from pressure transmitters enables smarter, faster responses to operational changes.

IPS Automation: Your Trusted Partner

At IPS Automation, we specialize in providing world-class pressure transmitters and automation solutions tailored to your industry’s needs. With our technical expertise and global partnerships, we ensure you’re equipped with the best-in-class technology to stay ahead.

Final Thoughts

Pressure transmitters may seem like a small component in your system, but they play a giant role in making sure everything runs smoothly. If you’re looking to modernize, secure, or scale your operations, upgrading your pressure monitoring systems might be a great place to start.

Ready to elevate your process control?

Contact IPS Automation today for a custom solution.