Injection Quills

Efficient Chemical Injection:

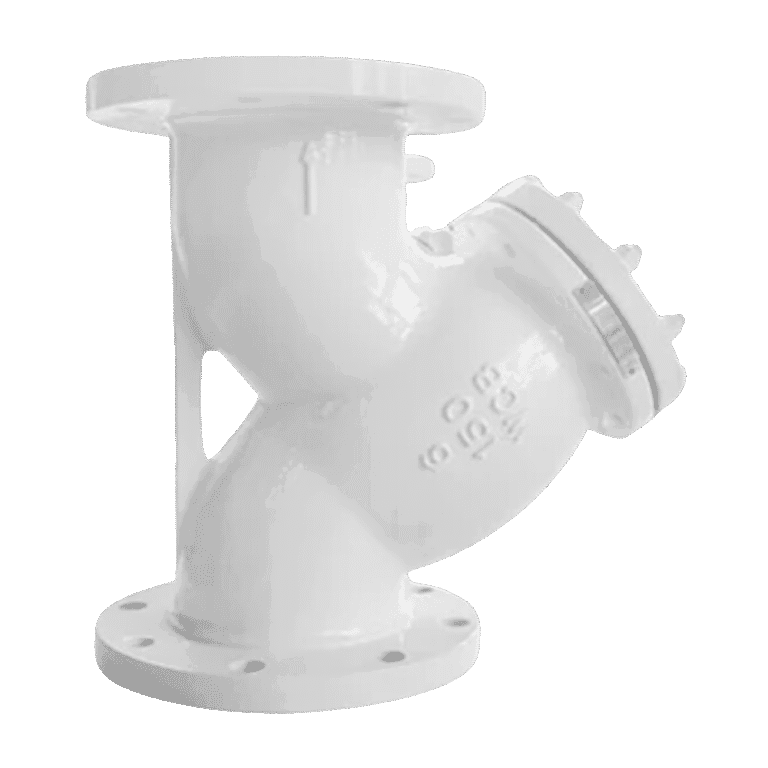

Designed to inject chemicals directly into the process stream, ensuring rapid and uniform mixing.Minimizes the risk of chemical stratification or uneven dispersion, optimizing process performance.Variety of Designs:

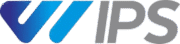

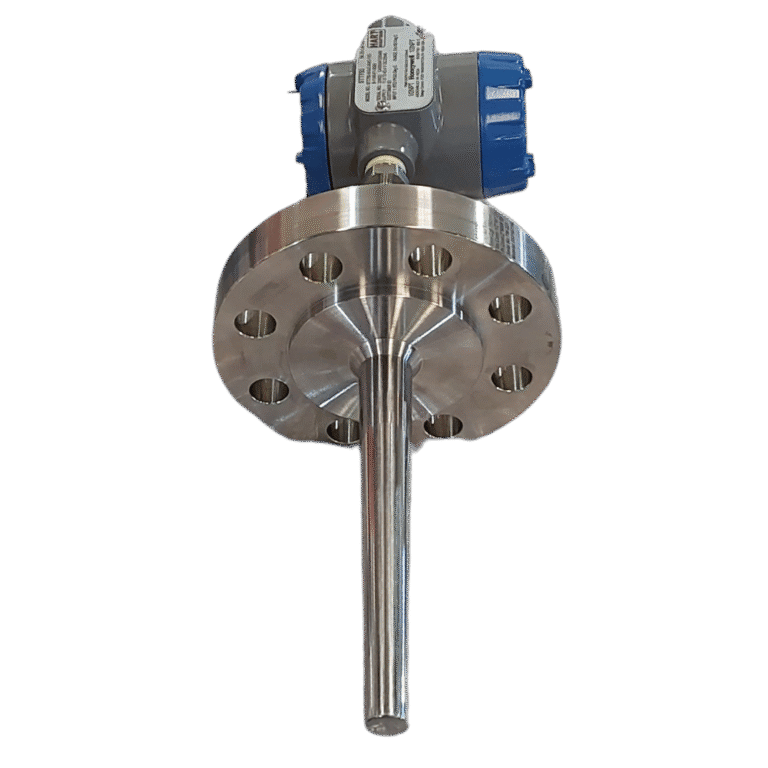

Flanged Injection Quills: Secure and easy installation with various flange sizes and ratings.Threaded Injection Quills: Ideal for quick and straightforward installation and removal.Retractable Injection Quills: Allow for safe maintenance and inspection without process shutdown.Non-Retractable Injection Quills: Permanent installation for continuous operation.High-Quality Construction

Made from corrosion-resistant materials such as stainless steel, Hastelloy, PVC, PTFE, and other alloys to withstand aggressive chemicals and harsh environments.Designed to handle high pressures and temperatures, ensuring reliable performance in various applications.Safety and Maintenance Features

Equipped with check valves to prevent backflow and ensure safe operation.Retractable designs feature isolation valves and safety chains for secure and easy maintenance.Customizable Options

Available in various lengths, connection types, and materials to suit specific application requirements.Custom designs and configurations available to meet unique process needs.Technical Specifications

| Measuring Range | Material Options: Stainless steel, Hastelloy, PVC, PTFE, PVDF, and other corrosion-resistant alloys and plastics. |

| Operating Temperature | Operating Temperature: Suitable for temperatures up to 200°C (392°F) or higher with special designs. |

| Operating Pressure | Operating Pressure: Can withstand pressures up to 100 bar (1450 psi) or higher with reinforced construction. |

| Material Options | Connection Types: Flanged: Various sizes and ratings (ANSI, DIN, JIS). Threaded: NPT, BSP, and other thread types. Welded: Permanent installation for high-integrity applications. |

| Float Size and Material | Check Valve Options: Spring-loaded or ball-type check valves to prevent backflow. |

| Indicator Board | Length and Insertion Depth: Customizable to meet specific process requirements. |

Applications

Oil and Gas

Oil and Gas Injection of corrosion inhibitors, demulsifiers, and other chemicals into pipelines, refineries, and offshore platforms.

Chemical Processing

Water Treatment Injection of disinfectants, coagulants, and scale inhibitors in water and wastewater treatment plants.

Water Treatment

Power Generation Chemical dosing for boiler feedwater treatment, cooling towers, and condensers.

Food and Beverage

Food and Beverage Precise injection of sanitizers, preservatives, and flavorings in food and beverage production processes.

Downloads

Benefits

Injection Quills are essential for industries requiring precise and reliable chemical injection solutions. With a variety of designs, high-quality construction, and customizable options, our injection quills ensure effective chemical dispersion, enhanced process efficiency, and improved equipment protection. By choosing our injection quills, you benefit from superior performance, safety, and operational efficiency in the most demanding industrial environments.For more information or to request a quote, please contact us at sales@globeunitedae.com.

- Enhanced Process Efficiency:

Ensures uniform mixing and dispersion of chemicals, optimizing process performance and reducing waste.

- Improved Equipment Protection:

Prevents localized corrosion and chemical stratification, extending the lifespan of critical equipment.

- Versatile Solutions:

Wide range of designs, materials, and customization options to suit diverse applications and process conditions.

- Safety and Reliability:

Equipped with check valves and other safety features to ensure secure and reliable operation.

- Cost-Effective:

Durable construction and low maintenance requirements contribute to reduced long- term operational costs.

We offer quality with the best materials and service

We offer quality, with the best materials and service

Our commitment to excellence is reflected in every product and service we deliver. Using only premium materials and advanced processes, we ensure unmatched quality, durability, and performance tailored to your needs.

Original Product

Inhouse Engineered, Innovative, Excellent product to redefine your expectations and embrace the extraordinary.

Warranty

We are confident about our quality products and covered our warranty to ensure client satisfaction.

Global Shipping

We offer our products Worldwide and we want you to experience our exceptional product at your doorstep. With Global customer base, We have earned trust globally.

100% Trust

Our commitment to 100% trust on our engineered product. Client trust is our most valued asset.